LOADING...

LOADING...

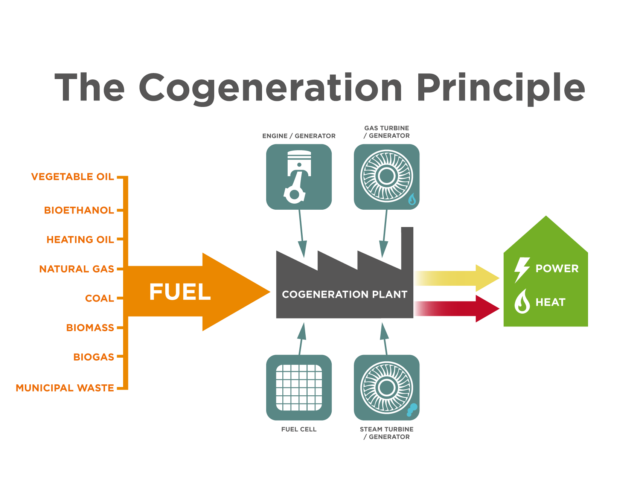

At Energimizer, we specialise in Combined Heat and Power (CHP) solutions, an innovative approach to energy generation that significantly enhances efficiency while reducing environmental impact. CHP, also known as cogeneration, seamlessly integrates the production of electricity and

thermal energy from a single fuel source. This dual-production process not only optimises energy use but also achieves efficiency levels exceeding 80%, far surpassing traditional energy generation methods.

CHP systems are designed to capture and repurpose the heat that would typically be lost in the electricity generation process. This recovered heat can then be used for heating, cooling, or other thermal applications, effectively reducing energy wastage and operational costs. Our CHP solutions can operate on a diverse range of fuels, including natural gas, biomass, coal, and biogas, offering unparalleled flexibility and the opportunity to leverage local and renewable energy sources.

Implementing a CHP system can transform your energy consumption, offering numerous benefits:

• Reduced Energy Costs: By generating electricity and heat simultaneously, CHP systems reduce the amount of purchased energy needed, cutting down operational expenses.

• Enhanced Environmental Performance: CHP systems significantly lower greenhouse gas emissions compared to conventional energy sources, aiding your business in achieving sustainability goals.

• Increased Energy Security: With on-site energy generation, CHP systems minimize dependence on the grid, enhancing reliability and protecting against power outages.

• Flexibility and Scalability: Tailored to meet the specific needs of your facility, our CHP solutions ensure optimal efficiency, whether for small commercial buildings or large industrial applications.

At Energimizer, we understand that the successful implementation of a CHP system requires careful planning and consideration. We work closely with our clients to assess their specific energy needs, considering factors like system size, fuel type, and the balance between electricity and heat demand. Our team ensures that each CHP solution is not only efficient and cost effective but also aligned with the long-term sustainability objectives of your business.

Choosing Energimizer means partnering with a leader in energy innovation, committed to delivering high-quality, sustainable, and efficient CHP systems. With our comprehensive approach, from initial assessment to ongoing maintenance, we guarantee a seamless transition to a more sustainable and cost-effective energy solution for your business. Discover the benefits of CHP and take a step towards a greener, more efficient future with Energimizer.

For more information on how CHP can benefit your business, contact us today.